Choose Section

A belt joint is where two ends of an abrasive sheet are permanently joined together to form an abrasive belt. KLINGSPOR uses multiple types of belt joints. The abrasive backing and intended application affect what type of joint is made.

Types of Belt Joints

| Type | Description | Image |

|---|---|---|

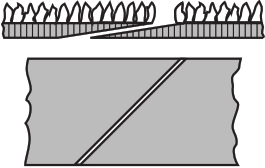

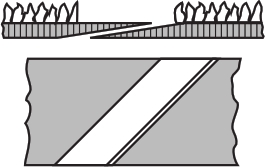

| #1 | Belt ends are overlapped with no grain removed off top of splice. Offers maximum protection against wear in the lap joints. For soft contact wheels, slack of belt operations and paper belts 150 and finer used in wide belt or lever stroke sanding. Standard joint for pump sleeves. |  |

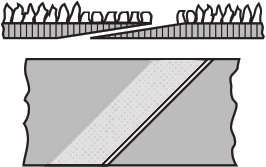

| #2 | Belt ends are overlapped with partial grain removed off top of splice (partial top-skived). Smooth running over platens or hard contact wheels for cloth belts 80 grit or finer. Seen mainly on edge sanders where bull nose or dead head sanding is being done. |  |

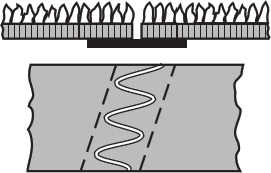

| #3 | Similar to #4 joint except the two belt ends are cut in an interlocking configuration, or zig-zag. Can be run in either direction. Available in grit size 80 or finer only. Designed specifically for glass grinding operations. |  |

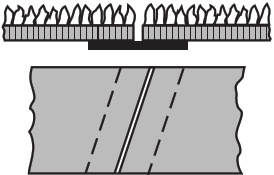

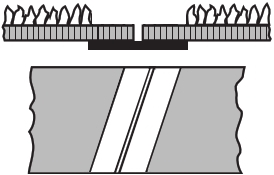

| #4 | "Butt splice", in which belt ends are butted together and joined by high-strength tape on the underside of the joint. It allows belt to run in either direction for greater belt life and convenience. Smooth running. The #4 is the most popular splice, suitable for a wide variety of applications and belt sizes. Strongest of the non-specialty joints. |  |

| #6 | Belt ends are overlapped with a complete grain removal off top of splice (fully top-skived) and cut at a 45-degree angle minimizing the amount of time the joint is in contact with the workpiece. It is used where a high degree of conformability in the joint area is required, such as mold sanding. IMPORTANT: For cloth belts only. |  |

| "T" Joints | A top skived #4 butt joint used on cloth belts 150 and finer for platen sanding operations on wide belt sanders or in grits 80 and finer on other belt operations where chatter is a problem when using a #4. IMPORTANT: Not for use on paper belts. For cloth belts only. |  |