Shoe Molding vs. Quarter Round: What's the Difference?

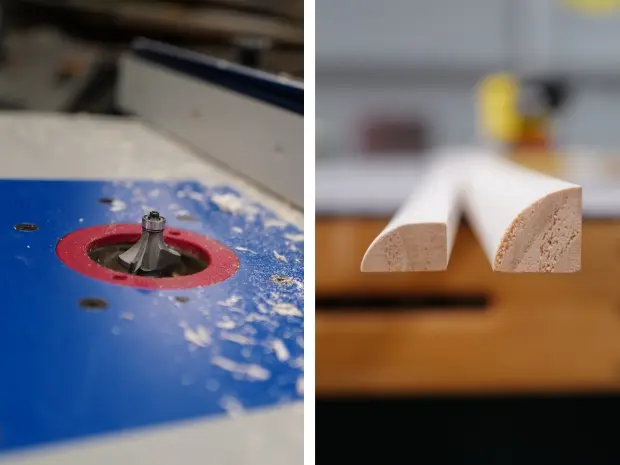

Step 1: Routing

To demonstrate the differences between shoe molding and quarter round, show you how they look like, how to cut and sand them for further use, we are going to use two different roundover router bits on each side of our workpiece. The size of the router bit determines the result you are going to get.

Quarter Round: The name Quarter Round has its origin in the size of the rounded part. Usually it's a quarter of a full circle. Our quarter round will have a final size of ¾" x ¾" x ¼".

Shoe Mold: Shoe Molds are usually ½" wide x ¾" tall x ½" rounded.

Recommended: #2009 and #2010 Roundover Router Bit

Tips

Before using the router bit, do a test run on another piece of wood to avoid uneven results. Adjust your bit as needed.

Step 2: Cutting

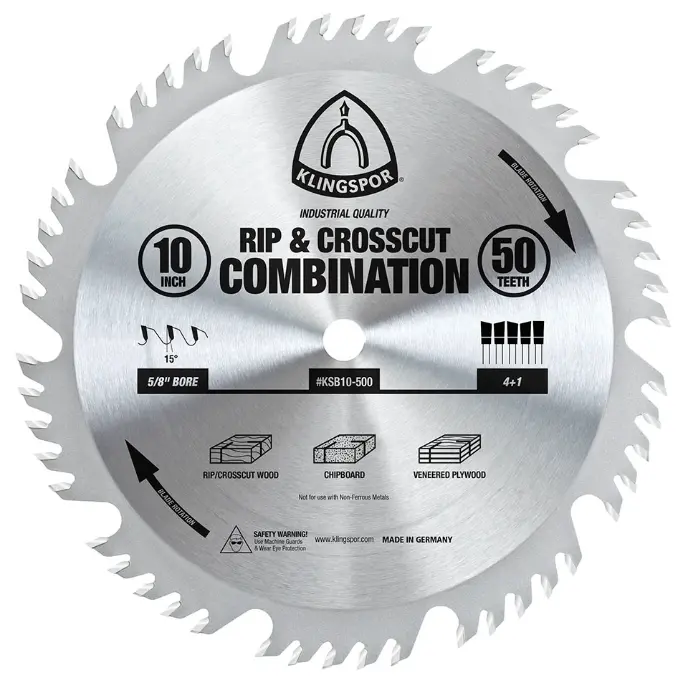

Next, cut your workpiece into the desired width. KLINGSPOR offers a variety of saw blades for any type of material you might use. We picked the Rip & Crosscut Combination blade for the wood we have used.

Recommended: KSB10-500 Rip & Crosscut Combination Sawblade

Step 3: Sanding

When we get to the point where the molding has been rounded and cut on the table saw, it's time to sand. You can do this by hand or with a random orbital sander, however, the by far best, easiest method using the least effort is KLINGSPOR's Fusion Foam.

Advantages

- Proprietary Grain-to-Foam-Adhesion: The grain is directly fused to the foam leading to reduced heat build-up and loading.

- High flexibility: Ideal for the use on flat and contoured surfaces, adapts to the shape of your workpiece.

- Operates within a grit range: Unlike other abrasives, that have a certain grit size, Fusion Foam operates within a grit range that can be reached by adjusting the RPM of your sander - no need to switch between products.

Recommended: Fusion Foam Pads 220-330 Grit