KLINGSPOR offers a well-rounded line-up of traditional abrasive products, along with technologically advanced diamond blades to open up market opportunities in construction, water works maintenance and repair, and installation.

As with all other KLINGSPOR high speed cutting and grinding tools, the diamond blade line is covered by the oSa seal of approval for safety.

Contents:

- Structure

- Segments & Gullets

- How to Choose the Right Blade

- Video Playlist

- Product Feature: The DT 900 ACR Diamond Blade

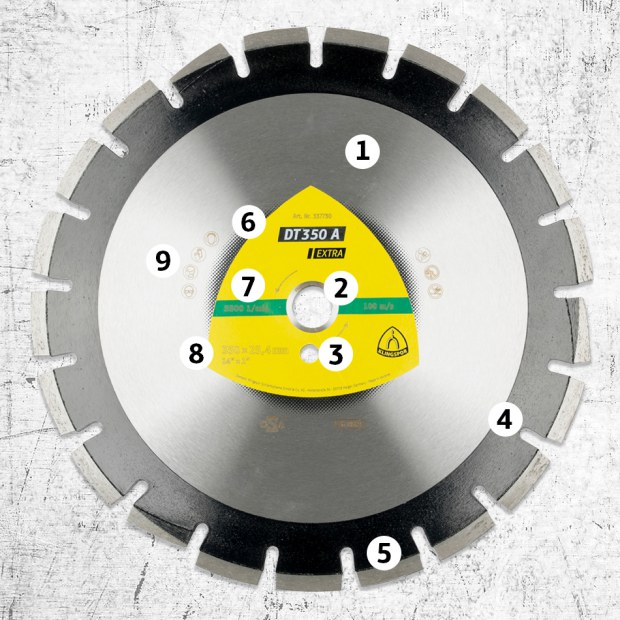

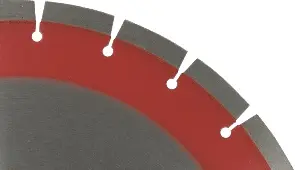

Structure

- Steel Core

The steel core is the foundation of the blade, providing stability. - Arbor Hole

The area where the blade connects to the power tool. The arrow around the arbor hole is the cutting direction of the blade. - Drive Pin Hole

An additional hole on certain diamond blades. - Gullet

The gullet is the gap between segments. It expels debris and reduces operating heat. - Segment

Working portion, contains diamonds. - Applications

The color around the edges of the KLINGSPOR triangle describes the tool's application range.- Asphalt: Black

- Tiles: Green

- Stone/Fireproof: Blue

- Concrete: Red

- Universal: White

- Maximum Operating Speed & Maximum RPM

The left side of the bar shows Maximum RPM (revolutions per minute), while the right side is the maximum operating speed given in meters per second. - Dimensions

Every diamond cutting blade contains information on dimensions in both units of measurement. - Safety Pictograms

The pictograms indicate how to use the diamond tools safely. They are located on both the left and right side.

Segments & Gullets

Segments are the teeth at the edge of a diamond blade where the diamonds and bond are held. They are also synthetic (man-made) for ideal shape and quality control. Meanwhile, gullets are the gaps between segments.

Type of Segments

There are various shapes of segments to suit their application. Below are some examples that KLINGSPOR has sold before.

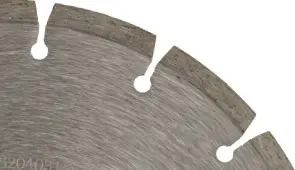

Standard Gullet

- Rapid feed rate

- Exceptional cutting properties

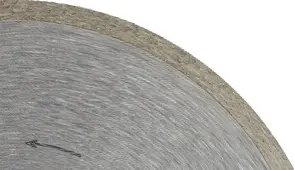

Continuous Rim

- Clean cutting edges

- Work with superior precision

- Short cutting times

Short Segments

- First-rate cutting performance

- Clean cutting edges

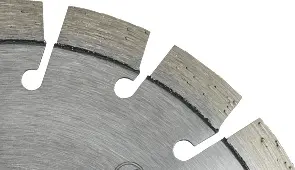

Narrow Gullet

- Clean cut

- Exceptionally smooth operation thanks to narrow segment spacings

Turbo Segments

- Exceptionally smooth operation

- Clean cutting edges

- Fast cutting speed

- Long service life

Wide Gullet

- High feed rate

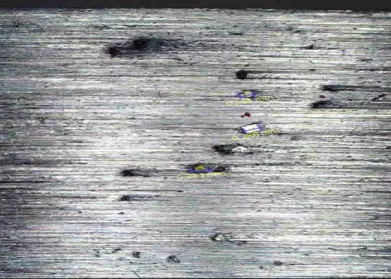

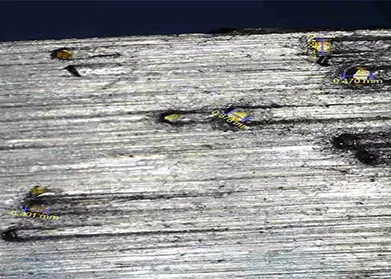

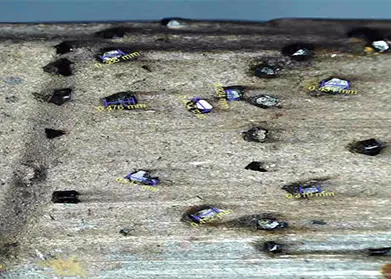

A Closer Look

Great stories are for everyone even when only written for just one person. If you try to write with a wide, general audience in mind, your story will sound fake and lack emotion. No one will be interested. Write for one person. If it’s genuine for the one, it’s genuine for the rest.

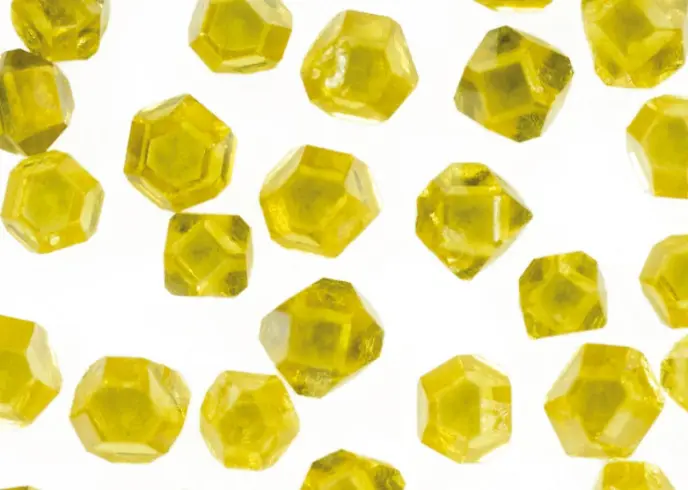

Zoomed-in

KLINGSPOR's yellow diamonds.

EXTRA Class

18-21% diamond concentration in segment of an EXTRA diamond blade & hard bond.

SUPRA Class

21-24% diamond concentration in segment of a SUPRA diamond blade & medium bond.

Special Class

24-27% diamond concentration in segment of a SPECIAL diamond blade & soft bond.

How to Choose the Right Guide

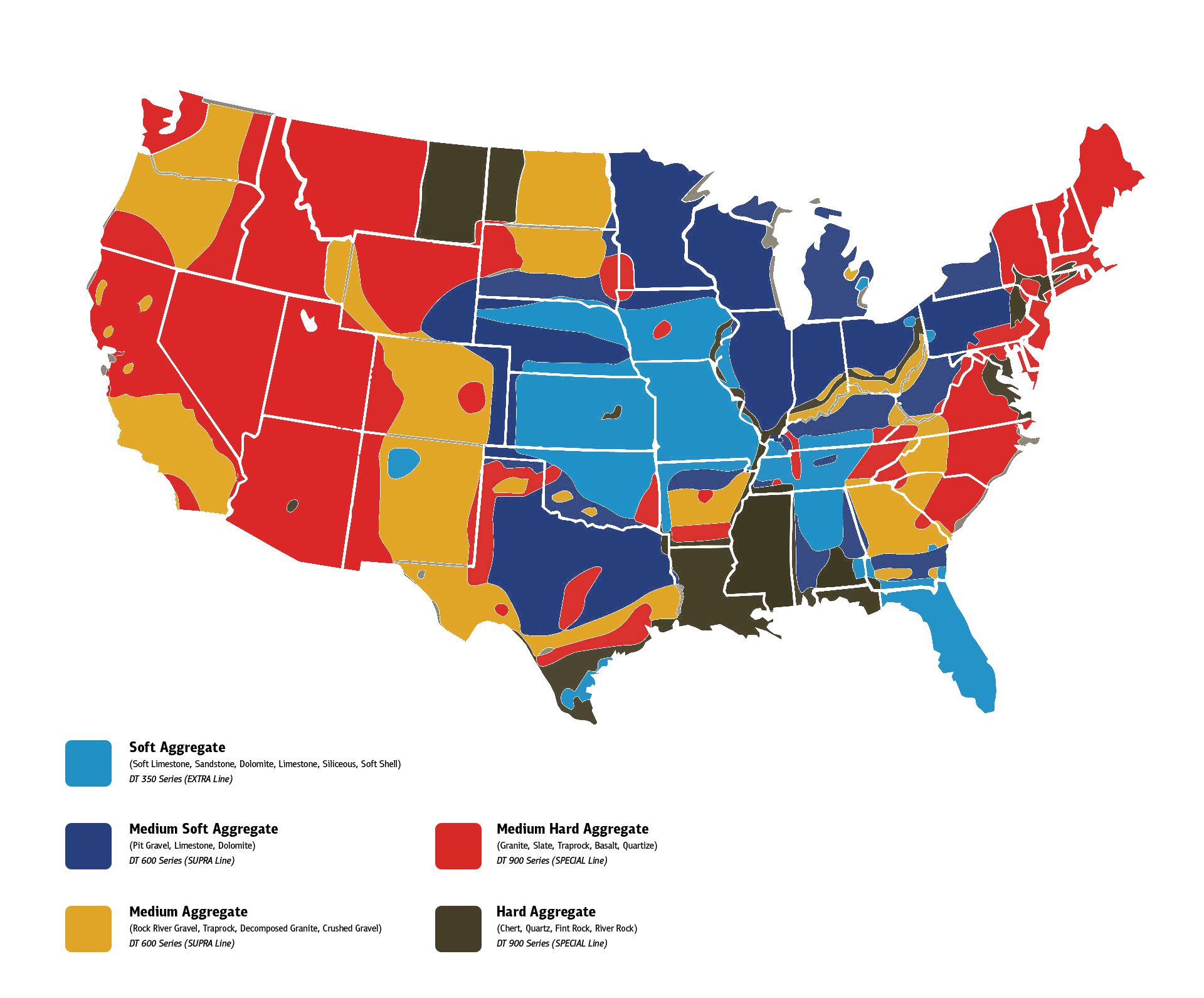

The biggest factor driving the decision for a diamond blade is the material that needs to be cut. Different areas in the United States have different aggregates.

Video Playlist

The DT 900 ACR Diamond Blade

Description

The applications for diamond blades are vast. A large variety of industries rely on these tools. The DT 900 ACR (All Cut Rescue) reaches a new level. Specifically made for rescue services, this blade should not be missing in any fire department or rescue team!

Advantages

- Very Aggressive

- Longevity: particularly stable connection between blade and diamond

- Wet & dry cutting on almost every material

Applications & Materials

Construction materials, concrete, glass, rubber, wood & wood-based materials, plastic, metal, power cables, PVC tubes, bitumen, and more.

Availability

- 9", 12" and 14" diameters

- 7/8", 1" and 20mm thicknesses

We recently did rescue training with a fire station. Two firefighters did the testing, cutting up the hood of an automobile, each using our blade and the competitor's in turn. We could observe that KLINGSPOR's blade seemed to cut faster and this was confirmed by both testers, adding that our blade seemed to cut more smoothly and required less feed pressure.